Why it matters: Electronic devices, which encompass anything from mobile phones to data centers, are notorious energy hogs. One solution could be to harness their heat directly to create a technique for on-chip energy harvesting. The problem has been that none of the few materials able to do this is compatible with current technology in semiconductor fabrication plants. Now, researchers from across Europe have created a germanium-tin alloy that can convert computer processors' waste heat back into electricity.

A research collaboration in Europe has created a new alloy of silicon, germanium, and tin that can convert waste heat from computer processors back into electricity. It is a significant breakthrough in the development of materials for on-chip energy harvesting, which could lead to more energy-efficient and sustainable electronic devices. Essentially, by adding tin to germanium, the material's thermal conductivity has been significantly reduced while still maintaining its electrical properties, making it ideal for thermoelectric applications.

The researchers are from Forschungszentrum Jülich and IHP – Leibniz Institute for High Performance Microelectronics in Germany, the University of Pisa, the University of Bologna in Italy, and the University of Leeds in the UK. Their findings made it onto the cover of the scientific journal ACS Applied Energy Materials.

The researchers sought to tackle the problem of the increasing energy consumption from electronic devices, most of which is dissipated into the environment in the form of heat. In Europe, about 1.2 Exajoule of low-temperature heat is wasted from IT infrastructures and devices per year – roughly equivalent to the primary energy consumption of Austria or Romania.

The solution, it seemed, was to harness the low-temperature heat – that is, below 80°C – from these devices directly for computer processors. The issue is there are very few materials available to convert the heat into electrical energy, and none of them are compatible with current technology in semiconductor fabrication plants.

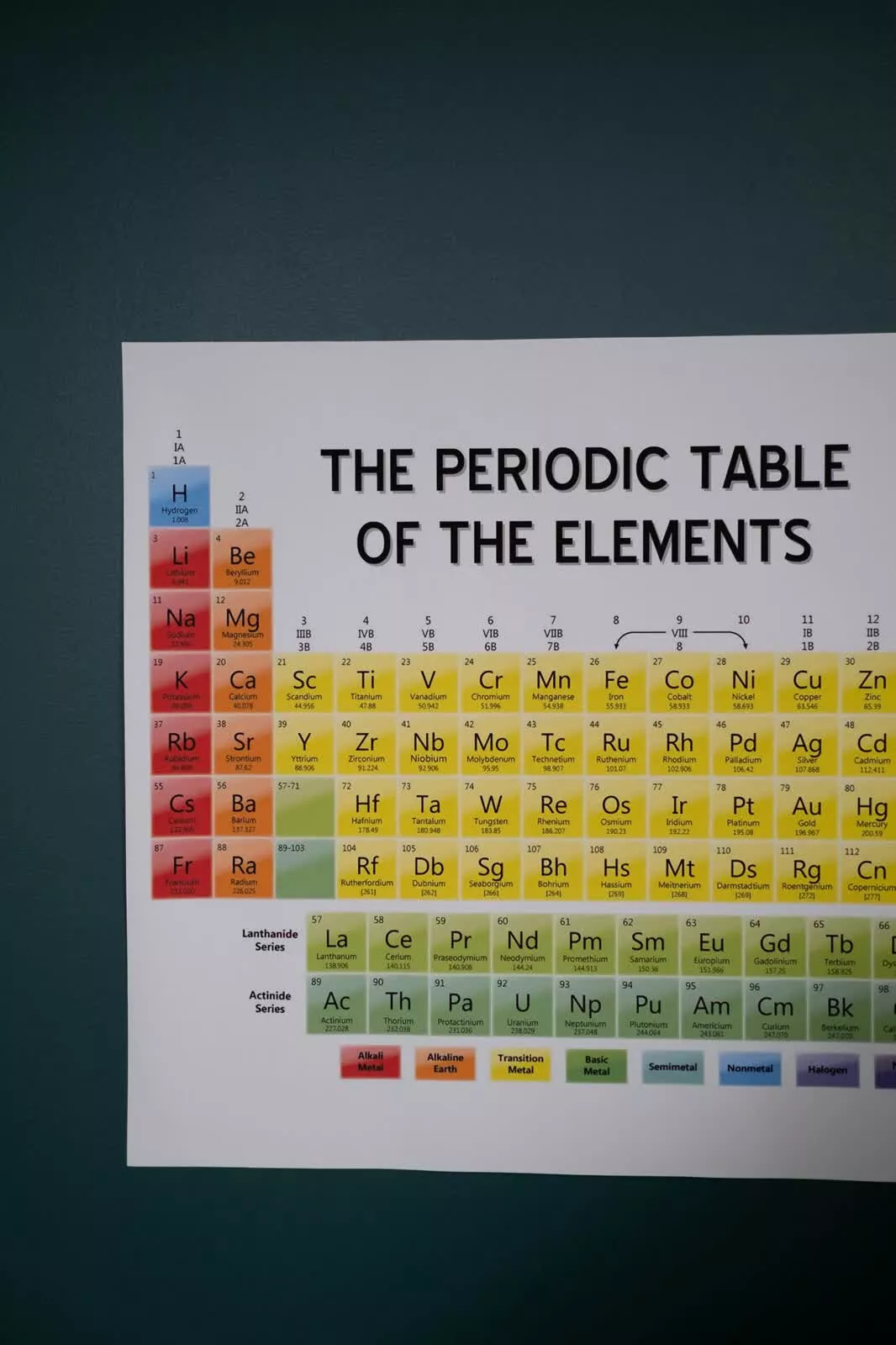

The new semiconductor alloy the researchers have created is composed of all elements in the 4th main group of the periodic table, allowing it to be easily integrated into the CMOS process of chip production. By integrating these alloys into silicon-based computer chips, it is possible to use the waste heat generated during operation and convert it back into electrical energy.

"Adding tin to germanium significantly reduces the material's thermal conductivity while maintaining its electrical properties, an ideal combination for thermoelectric applications," explains Dr. Dan Buca, leader of the research group at Forschungszentrum Jülich.

This research could also lead to improved performance of devices. By exploiting the alloying properties of the Group IV elements, the application areas expand to include thermoelectrics, photonics and spintronics. That is because each technology brings unique capabilities: thermoelectrics for energy harvesting, photonics for light-based data transmission, and spintronics for magnetic-based information processing. The monolithic integration of these technologies on the same chip has been an ambitious long-term goal of silicon-based technology for several reasons.

For example, photonic components can enable faster data transmission and lower power consumption compared to traditional electronic interconnects. Also, by combining multiple functionalities on a single chip, rather than requiring separate chips for each technology, more compact devices can be developed.